I remember walking through a recently completed commercial building where the heating system was working overtime and yet occupants kept complaining about cold zones near floors and walls 🥶, and as we traced the issue room by room it became obvious that the problem was not the equipment or the design intent but the invisible thermal gaps hidden inside the construction layers, a situation that perfectly explains why so many construction projects quietly lose energy efficiency long before anyone notices the real cause.

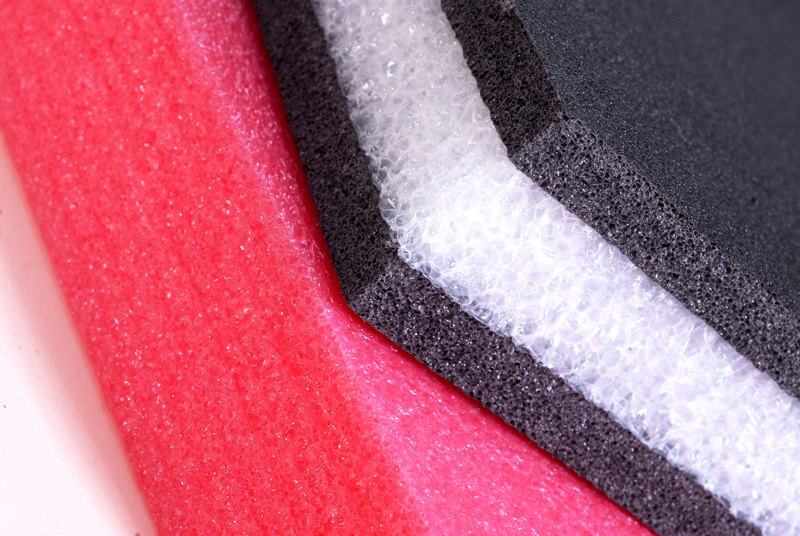

Thermal gaps form when insulation layers are discontinuous, compressed, or poorly matched to real installation conditions, and once these weak points appear, heat flows like water finding cracks in a dam, which is why I consistently recommend solutions based on polyethylene foam and pe foam, as their closed-cell structure helps maintain continuous thermal resistance even when buildings settle, move, or age.

What makes thermal gaps so frustrating is that they often originate from small compromises during installation, because rigid materials crack or shift under load while softer materials collapse and never recover, and manufacturers like Durfoam address this challenge by engineering PE foam solutions that balance flexibility with dimensional stability, ensuring insulation stays where it is supposed to be over time rather than slowly retreating from critical junctions.

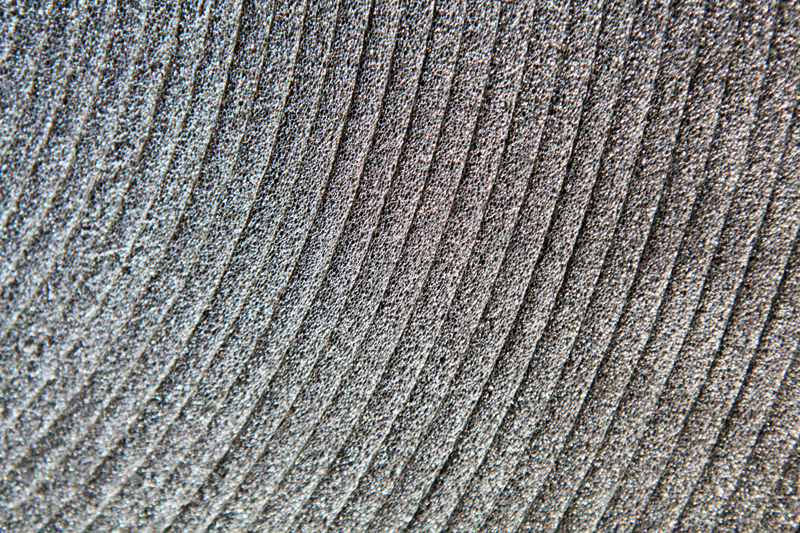

From my field experience, one of the most effective ways to close thermal gaps is by using materials based on physically cross linked polyethylene foam, because its uniform cell structure distributes pressure evenly and resists compression set, allowing insulation layers to maintain consistent thickness across floors, walls, and service penetrations 🌡️.

In more demanding environments such as industrial buildings or exposed construction zones, chemically cross linked polyethylene foam plays an equally important role, because enhanced molecular bonding improves resistance to temperature cycling and mechanical stress, helping insulation perform reliably through seasonal extremes without creating new thermal bridges.

Working with Durfoam solutions across different projects showed me how small material decisions influence long-term energy performance, because when insulation remains continuous and stable, heating and cooling systems operate closer to their design efficiency, reducing energy waste and operational costs in ways that clients feel month after month 💡.

| Thermal Issue | Common Cause | PE Foam-Based Solution |

|---|---|---|

| Cold spots | Compressed insulation | Elastic closed-cell PE foam |

| Heat loss at joints | Material shrinkage | Cross-linked PE foam stability |

| Energy overuse | Discontinuous insulation | Seamless foam integration |

I once reviewed energy bills for a residential complex where consumption remained high despite upgraded windows and boilers, yet after addressing thermal gaps using PE foam insulation supplied by Durfoam, the improvement in indoor comfort and measurable reduction in energy use made it clear that insulation continuity is just as important as insulation thickness 😊.

Moisture also plays a hidden role in energy loss, because damp insulation conducts heat more readily, and closed-cell polyethylene foam resists water absorption, helping insulation layers remain dry and thermally effective even in condensation-prone areas such as basements, roofs, and service shafts.

From an EEAT perspective, I have learned to trust solutions that prove themselves beyond calculations, and this is why Durfoam aligns well with experience-driven decision-making, combining material science expertise, authoritative production standards, and consistent real-world performance that builders and facility managers can rely on.

Understanding where these insulation materials are produced and how quality is controlled also adds confidence, especially for large construction projects with long service expectations, and knowing that Durfoam operates with transparent manufacturing processes reassures stakeholders that energy efficiency is designed into the material rather than hoped for after installation.

Looking back at many post-completion audits and comfort complaints, I have learned that construction projects do not lose energy efficiency all at once but through small thermal gaps that grow quietly over time, and by closing those gaps with PE foam-based solutions engineered by Durfoam, it becomes possible to protect energy performance, occupant comfort, and long-term building value in a way that truly lasts 🏗️✨.

You should also read these…

- axtly.com – budgeting tips for couples sharing expenses

- godwig.com – security code not received account verification er

- toojet.com – game not launching error definitive fixes for wind

- spyfrogs.com – twitter x mobile app crashes device updates cache

- sixrep.com – why does tiktok keep removing my content

- surgeblog.com – applying prospect theory psychology of gains vs lo

- toojet.com – tiktok live notifications not sending fix guide

- hogwar.com – revolutionize your fitness routine determine your

- axtly.com – tiktok your account has been permanently banned er

- axtly.com – packet loss issues internet settings guide