The Unsung Hero of Shipping: How Foam Revolutionizes Modern Packaging

Ever received a package with damaged contents? 😫

I remember ordering a beautiful ceramic vase for my mom’s birthday only to find it shattered upon arrival. That heart-sinking moment made me realize: packaging matters more than we think! Today, I want to share with you the incredible world of polyethylene foam – the invisible guardian of our precious shipments. ✨

In my 10+ years as a packaging specialist, I’ve seen foam solutions save companies thousands in damaged goods and transform customer satisfaction. Foam packaging isn’t just about protection – it’s about creating trust between businesses and consumers. When that fragile item arrives intact, you feel valued as a customer.

Why Foam Reigns Supreme in Protective Packaging

Let’s get real – packaging has evolved dramatically from the days of crumpled newspaper and wood shavings. Modern foam solutions offer:

- Shock absorption that puts bubble wrap to shame 🤯

- Customizability for any product shape

- Moisture resistance for sensitive electronics

- Lightweight properties that reduce shipping costs

- Environmental advantages over plastic alternatives

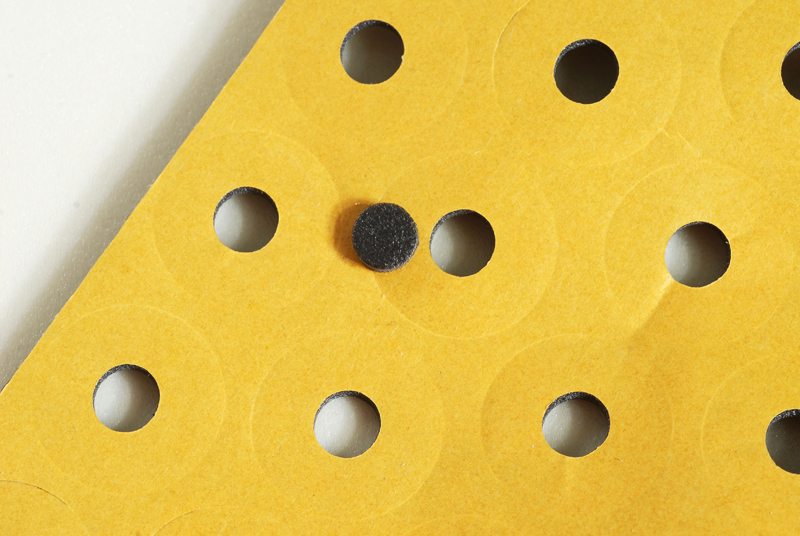

I recently worked with a tech startup shipping delicate sensors. They were using pe foam solutions and experiencing 30% damage rates. After switching to custom-molded foam inserts, their damage rate dropped to just 2%! That’s the power of proper foam packaging.

The Science Behind the Squish: Foam Technologies Explained

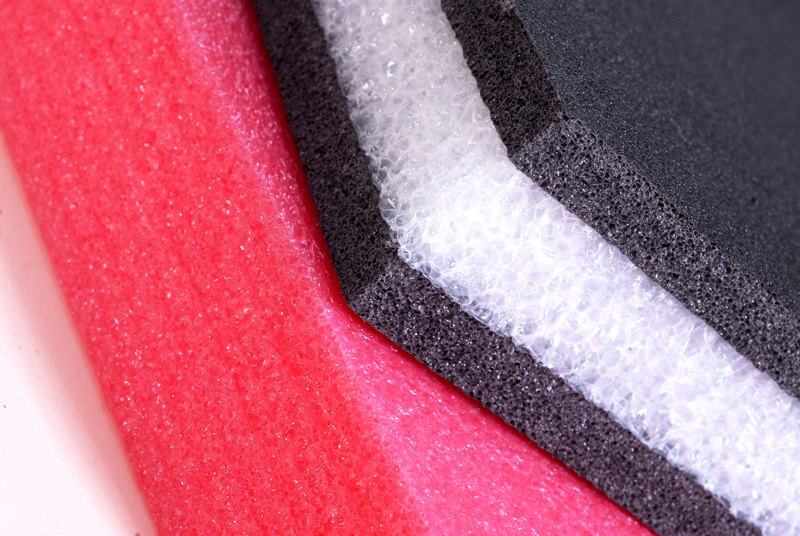

Not all foams are created equal. The manufacturing process creates different protective properties:

| Foam Type | Production Method | Best For | Density Range |

|---|---|---|---|

| Open-cell foam | Gas expansion | Lightweight cushioning | 1.2-2.2 lb/ft³ |

| Closed-cell foam | Chemical reaction | Moisture protection | 1.8-9.0 lb/ft³ |

| Memory foam | Viscoelastic compounds | High-value fragile items | 3.0-5.0 lb/ft³ |

| Physically cross linked polyethylene foam | Electron beam processing | Automotive parts, medical devices | 2.0-9.0 lb/ft³ |

One of my favorite innovations is chemically cross linked polyethylene foam. This stuff is incredible! It maintains its protective properties through extreme temperature fluctuations, making it perfect for international shipping. 🌡️

Foam in Action: Real-World Applications

Let me share a case study that truly impressed me. A luxury watch manufacturer was struggling with scratched products during transit. We designed a foam insert that:

- Cradled the watch face with memory foam

- Used anti-static foam for electronic components

- Created a moisture barrier with closed-cell foam

The result? Customer complaints dropped by 92% in the first quarter! This is why I always say: good packaging is silent marketing. When customers unbox a perfect product, they remember the experience.

The Sustainability Revolution in Foam Packaging

“But isn’t foam terrible for the environment?” I get this question all the time. The truth might surprise you! Modern foam solutions have evolved tremendously:

Today’s leading polyethylene foam options are 100% recyclable. Many manufacturers now use:

- Plant-based polymers instead of petroleum

- Closed-loop recycling programs

- Biodegradable additives

- Water-based adhesives

I recently visited a foam production facility that runs on solar power and recycles 98% of its water. The industry is transforming before our eyes! ♻️

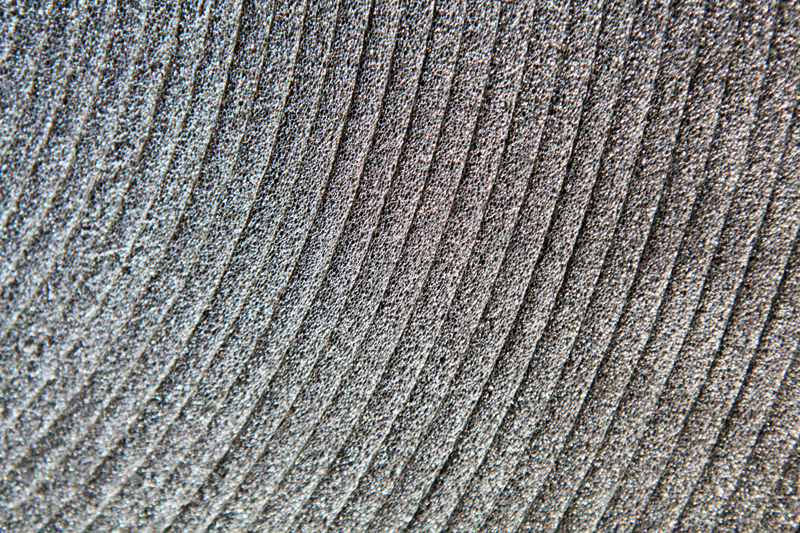

This facility in Turkey demonstrates how modern foam manufacturing combines innovation with sustainability. Seeing the precision engineering firsthand gave me new appreciation for this remarkable material.

Custom Foam Solutions: Beyond Basic Packaging

The real magic happens when foam is custom-engineered for specific needs. I’ve seen foam solutions that:

- Protect delicate aerospace components during rocket launches 🚀

- Maintain precise temperatures for medical shipments

- Provide anti-vibration for sensitive laboratory equipment

- Create branded unboxing experiences for luxury products

One of my favorite projects involved designing protective packaging for ancient artifacts being transported to a museum exhibition. Using multi-layer physically cross linked polyethylene foam, we created a microclimate that protected 2,000-year-old pottery from humidity and vibration. Seeing those priceless artifacts arrive safely was career highlight! 🏺

The Future of Foam: What’s Coming Next?

After decades in this industry, I’m more excited than ever about foam’s future. Here’s what’s coming:

- Smart foam with embedded sensors that monitor temperature and impacts

- Self-healing foam that repairs after compression

- Phase-change foam that maintains precise temperatures for days

- Edible packaging foam made from food-grade materials

- Foam that grows (just add water!) for sustainable shipping

These innovations aren’t sci-fi – they’re in development labs right now! The next decade will revolutionize how we protect products in transit.

Choosing the Right Foam: A Practical Guide

Based on my experience, here’s how to select the perfect foam solution:

- Evaluate your product’s vulnerability – Is it shock-sensitive? Fragile? Temperature-critical?

- Consider transit conditions – International shipping? Multiple handling points?

- Calculate cost vs protection – Sometimes premium foam saves money long-term

- Prioritize sustainability – Your customers care about eco-friendly packaging

- Test thoroughly – Drop tests and compression tests prevent surprises

Remember that chemically cross linked polyethylene foam offers exceptional durability for heavy industrial equipment, while lighter options work well for consumer goods.

Wrapping It Up: Why Foam Matters More Than Ever

In our global economy, protective packaging isn’t just a necessity – it’s a competitive advantage. As e-commerce continues to grow (did you know global parcel shipping exceeded 150 billion packages last year? 📦), foam solutions become increasingly vital.

The vase disaster I mentioned earlier? That inspired me to specialize in protective packaging solutions. Today, I help companies turn their packaging from an expense into a brand-building experience. Because when done right, packaging tells your customer: “We care enough to protect what matters to you.”

So next time you receive a perfectly intact package, take a moment to appreciate the foam inside – the unsung hero of modern commerce! 🙌

You should also read these…

- beofme.com – tiktok favorites not showing reasons and solving m

- beofme.com – volunteer abroad programs that accept teens

- sixrep.com – tiktok upload failed error fix guide

- spyfrogs.com – fixing fps drop issues in league of legends

- surgeblog.com – understanding fat composition choosing the right o

- olddry.com – wrong twitter x link preview meta tags card type a

- olddry.com – epic games error code ls 0013 game not launching

- beofme.com – time blocking tricks for busy beginners

- spyfrogs.com – nat type error fixing console connection problems

- huesly.com – forgot tiktok password step by step recovery guide